Globe-trotting Tony Rodgers is a difficult man to pin down for long. The group chief executive of Emtelle has touched down at his Glasgow office hours before zooming off again to the United Arab Emirates (UAE) for a big day with an Emirati prince.

The day after Rachel Reeves’s ‘invest, invest, invest’ Budget, a ceremony in Abu Dhabi featuring Emtelle, the Borders-based manufacturing business, shows what ‘scale and pace of investment in industry’ actually means in other jurisdictions.

While the UK Government is stretching every sinew to raise taxation to deliver growth, the ease with which oil-rich Arab nations such as the UAE can attract manufacturing, offering incentives to build new factory premises and drive investment, must be a lesson for both Prime Minister Sir Keir Starmer and First Minister John Swinney in Scotland.

People don’t want to be without the fourth utility – which is data. Yet the United States is miles behind in its fibre journey compared to the rest of the world.’

Tony Rodgers – the recent winner of EY’s International Entrepreneurial Leader of the Year for Scotland – is an ebullient working-class Scot from the Ayrshire coast who has pulled himself to the top. He’s now the Flying Scotsman moving around the globe.

Emtelle, with its headquarters in Hawick, is a privately-owned company making fibre-optic cabling for the world. It began pressing out plastic coat-hangers for the Borders garment industry then converted its machines to the extrusion of high-density polyethylene to make fibre optic cable. Plastic – like steel – is a worldwide traded commodity. Sadly Scotland, despite its oil and gas resources, does not make this vital commodity for the likes of Emtelle.

Today Emtelle is a global manufacturer of pre-connectorised blown-fibre cable and ducted network solutions.

The company’s centre of excellence in Scotland is where solutions director Colin Kirkpatrick leads a ‘brains-trust’ of innovation, developing more than 40 patents and 36 trade marks, all specific to the preconnectorisation of fibre.

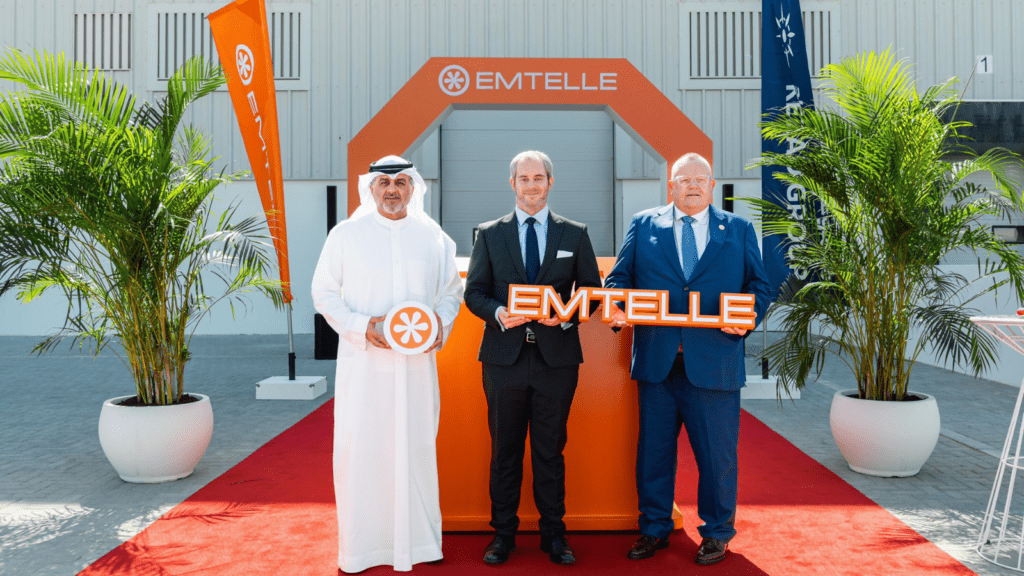

Emtelle has recently opened a $50m innovation and manufacturing facility in Khalifa Economic Zone Abu Dhabi (KEZAD). It is a 48,000 sq metre facility that has been welcomed by the UAE.

Abdullah Al Hameli, CEO of the Economic Cities & Free Zones, AD Ports Group, said: “Emtelle’s new facility is a welcome addition to our thriving ecosystems for advanced manufacturing. It reinforces KEZAD’s growing appeal as an international hub for business and puts Abu Dhabi on the global industrial development map.”

Rodgers is delighted with the new factory, which has access to local polymers that are a fraction of the cost of the supply in the UK.

“We are an international business in different time zones. The guys in the UAE are in a few hours before us in Glasgow, while the guys in the States are in a few hours after us. This new facility is a key part of our strategy to increase capacity and efficiency in one of our fastestgrowing markets.”

The KEZAD hub will help reduce lead times for fibre, and its strategic location, logistics infrastructure and government aid have all been instrumental in making this happen.

Emtelle is also preparing to crank up manufacturing in the United States, where its factory in Fletcher, North Carolina, is churning out fibre optics for a vast nation increasingly burying cable in the ground.

“People don’t want to be without the fourth utility – which is data. Yet the United States is miles behind in its fibre journey compared to the rest of the world.”

Rodgers says the US is going to be the biggest market in the world for the next ten years.

“North Carolina is just recovering from the aftermath of the very serious flooding. Thankfully, we didn’t lose any people, and we only had a couple of inches of water in the factory floor. The damage to our site was minimal but the main thing was there was no electricity for a week and half and no water for two weeks.”

Rodgers points out the fibre optic cable industry had been in the doldrums because of high interest rates, but increasingly, high-speed connectivity is viewed as a way of driving the economy.

“The biggest problem in the States is a lot of their network is aerial, so when they get a flood, a storm or a typhoon, all the utilities are damaged and they have to rebuild the network every time. As the nation migrates from copper to fibre, the speed of repairing a copper network is a couple of hours, compared to the speed of repairing a fibre network, which depending on the damage could be weeks,” he says.

The US factory investment is viewed as a smart move for Emtelle in 2025 given the election of Donald Trump and his views on tariffs.

“President Trump, like a lot of other countries around the world, is now becoming a protectionist about the economy. One of the big things for government funding projects is BABA – Build America, Buy America – so that it has to be Americanmanufactured and supplied. Now with our expanding manufacturing base there, this will definitely help us.”

Blown fibre means cables can be pushed along existing underground conduits up to 300 metres without digging up streets. This is a winning proprietorial approach from Emtelle, supplier to the major telecom and cable companies. Furthermore, the true Scottish trade-marked invention, pioneered in Hawick and Jedburgh, around the splicing and connection of each cable strand, is greatly increasing the reliability of each link. So how does Emtelle protect its ‘secret sauce’?

“We’re fortunate we have great intellectual property lawyers and we have a fantastic design and development department in Hawick who are acutely aware of the need to do something unique and patentable. We have a plethora of patents across a lot of our ideas. We are very strong on intellectual property.

“As a leader in this market, we know we have to protect this and not allow anyone to piggyback on our development,” he says.

Rodgers is a 100 per cent believer in manufacturing and its role in driving economic change.

“I know we are talking a lot in Scotland about advanced manufacturing, and that is a good thing. But before we get to the advanced stage, we need to undertake basic manufacturing in this country. We need people to appreciate and understand its vital nature. I don’t think enough is being done to promote and develop Scottish manufacturing,” he says.

Bringing more people into the manufacturing work environment is one of the key challenges for Rogers.

“Trying to get people working in manufacturing, both in Scotland and globally, is a huge struggle. I hear people saying that no-one wants to work on the shop floor, whether that is Denmark, Germany, the United States and the Borders. We don’t have this problem in the Middle East where our people get the best accommodation and holidays.

‘When you were younger, if you got an apprenticeship, you were throwing cartwheels because you were going to get a trade’

“What we are trying to do is give our teams excellent training. We’ve got a great relationship with Heriot-Watt University in the Borders, and now out in the UAE, where we are putting people through graduate apprenticeship schemes, and gaining degree qualifications.”

He singles out Borders College for praise after it set up a specialist plastics course, which means Emtelle can send its apprentices to college. HeriotWatt University also has a new campus in Dubai. Education is at a premium. This is all part of the ‘Emiratisation’ process in which the Gulf states seek more skilled people, bringing in new employment and are not simply dependent on government money. Moreover, Rodgers is proud that Emtelle has agreed to pay the school fees for shop floor workers who remit much of their salaries back to their Indian and Pakistan homelands.

“We are very big on both executive and shop floor education.”

However, as a trained accountant who began in an indentured office at 16, he is concerned that the work ethic of turning up for employment has been diminishing.

“When you were younger, if you got an apprenticeship, you were throwing cartwheels because you were going to get a trade. There is not the same stick-ability now.”

What is driving the chief executive as his company pushes to get its group turnover back to £400m a year?

“The money is good, but money is not everything; the thing that drives me is that we need to make sure that as many people, in as many places around the world, get access to high bandwidth internet connections. We need to do this because the digital divide is getting worse in some places – and I want to see us doing something about this.

“Having come from an under-privileged background in Ayrshire, one of the single biggest things that makes a difference is education. What’s driving attainment in education is having access to high quality broadband.”